Pattern Preparation/Prototyping

We offer a full service shop capable of producing new pattern equipment with a variety of materials and performing customer revisions, rigging, and repairs.

Core Making

Complete No-Bake sand and shell sand capability.

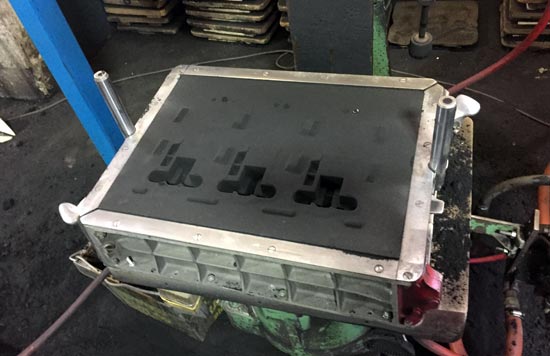

Molding

The pattern is packed with a sand and binder mixture that is controlled by one of eight No-Bake sand mixers.

Melting

Customer specified alloys are melted with one of 3 induction electric furnaces.

Pouring

Once the desired content and temperature are reached, molten metal is transferred into pouring ladles and poured through the gating system into the mold.

Grinding

Gating, risers, and vents materials are removed.

Shot Blasting

Blasting cleans any remaining sand and coating from the casting.

Final Inspection

Each casting goes through final inspection before it is sent to the shipping department.

Shipping

Castings are packaged or palletized and ready for shipping.